Complied matters

To adhere films with 1sq. meter or more without scratches or air bubble and to an accuracy of 0.5mm. Customer attempts with the existing machines were unable to increase tact-time. Therefore, customers should install several lines to cover production volume. We offer machines with dramatically improved tact-time and keeping quality. Thus, the customer could avoid not only the investment for the machines but also clean room expansion. We can also contribute to running cost reduction over the long term.

Technology used

-

Roll film transportation technology

We have the technology to transport film for optics application with high accuracy without scratches.

See machines using this technology > -

The Machine on Roll film transportation technology

-

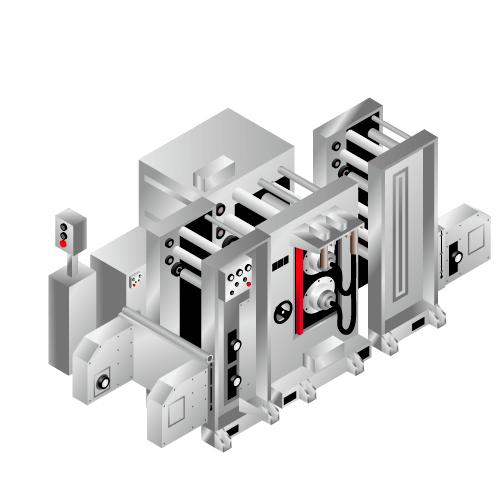

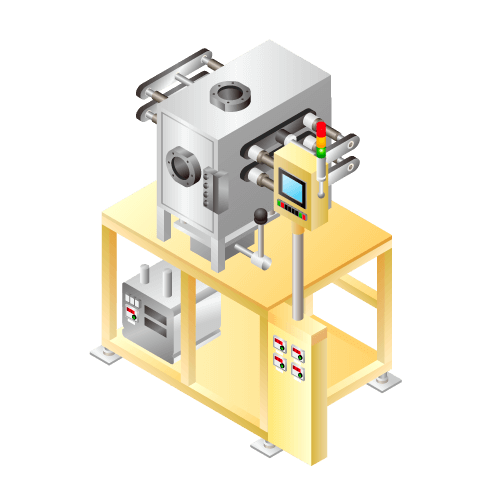

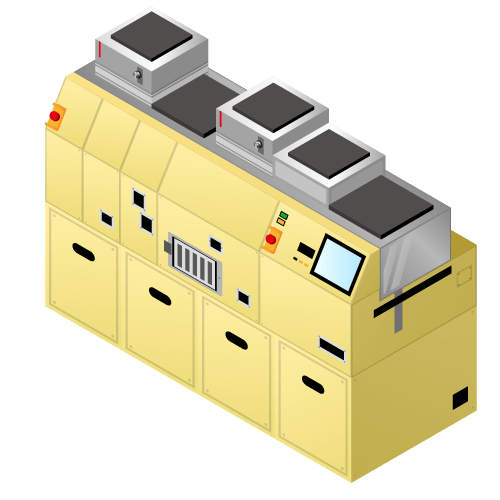

Roll press for lithium-ion secondary batteries etc.

Machine to increase density of electrode material by pressing positive electrode or negative electrode of lithium-ion etc. with roller continuously.

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

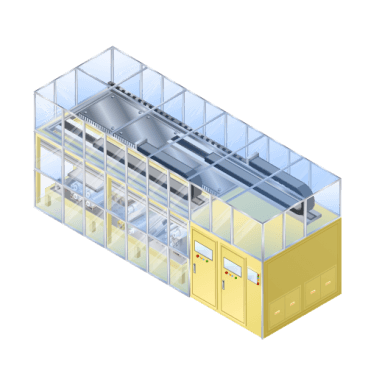

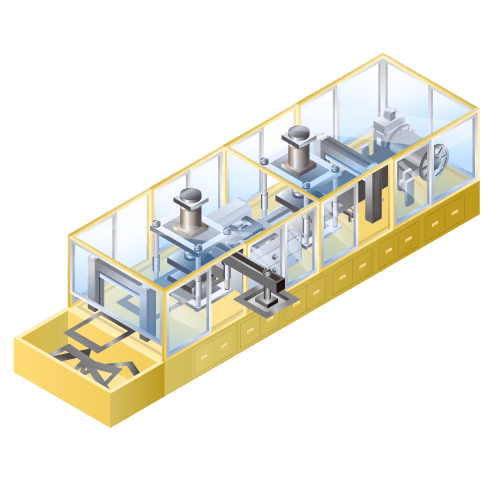

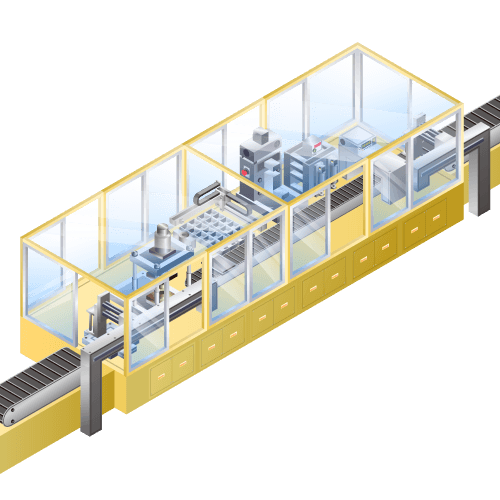

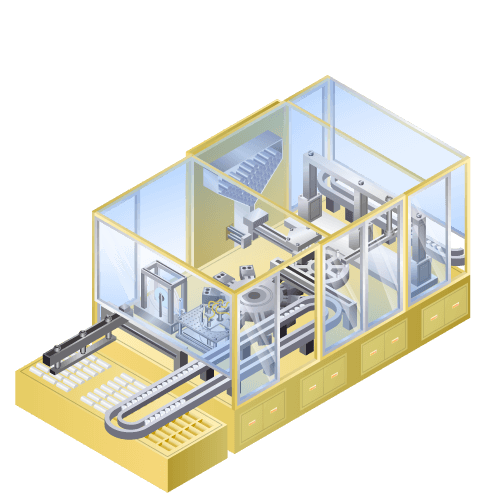

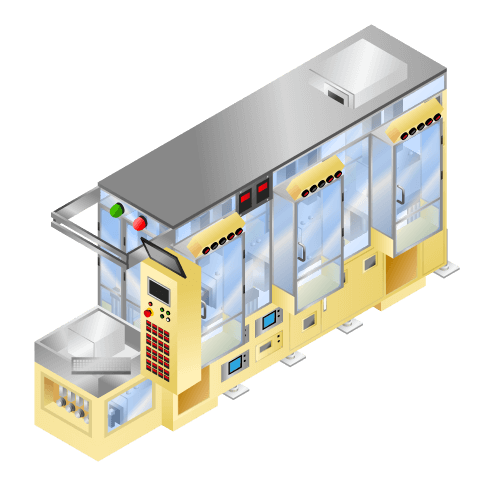

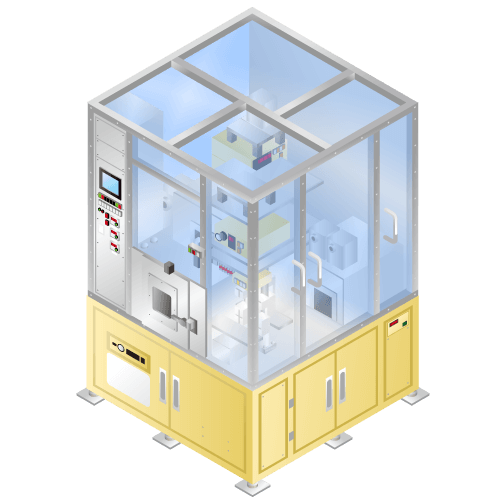

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

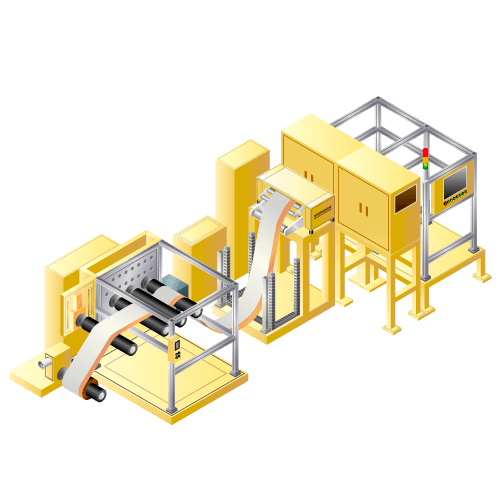

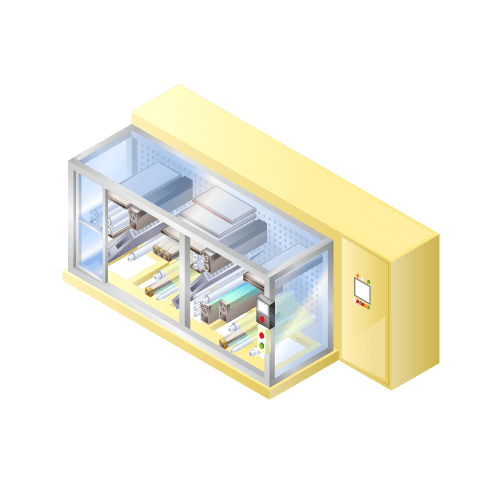

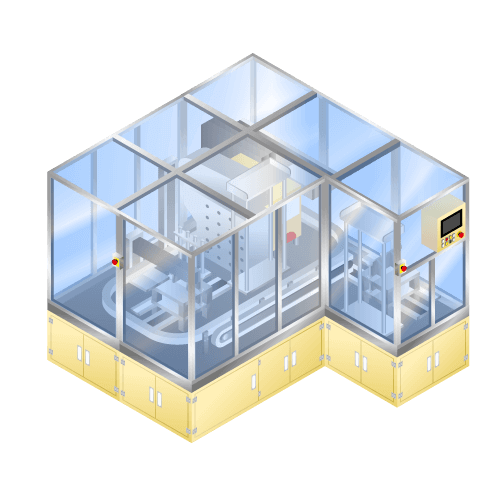

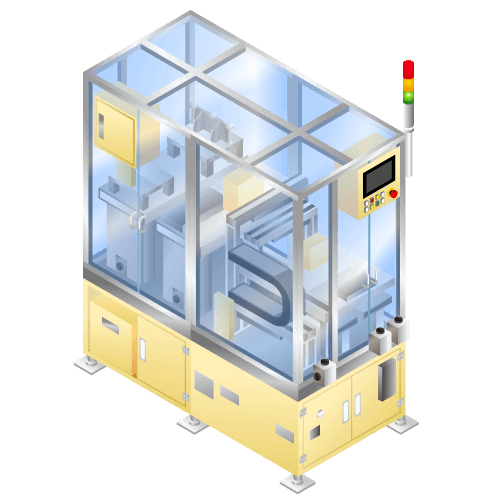

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

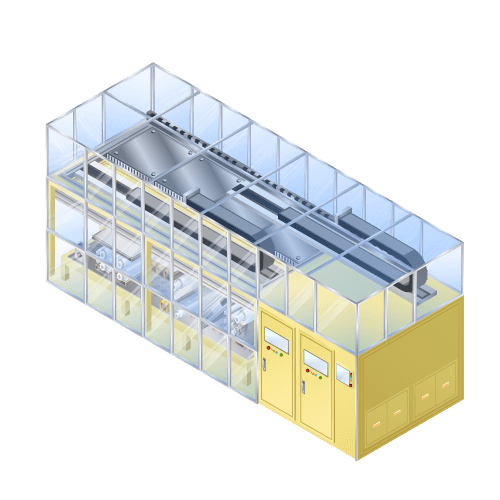

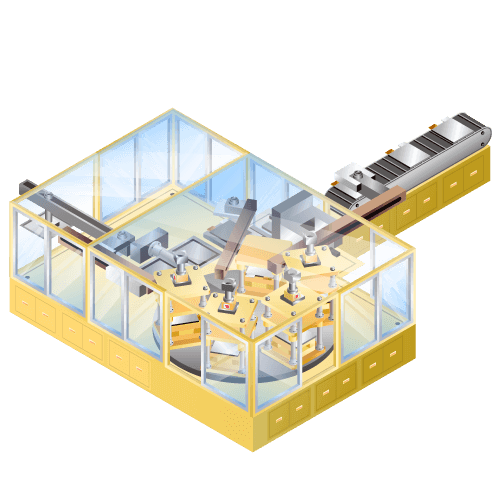

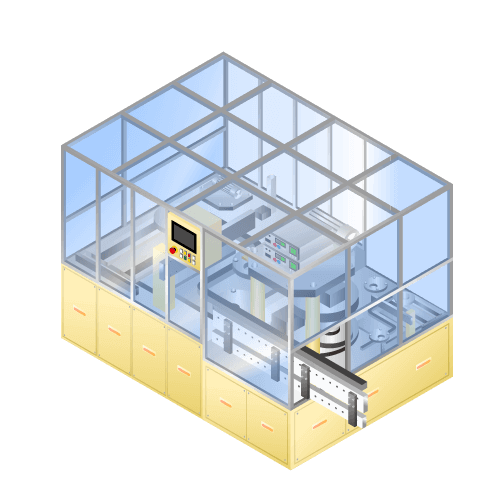

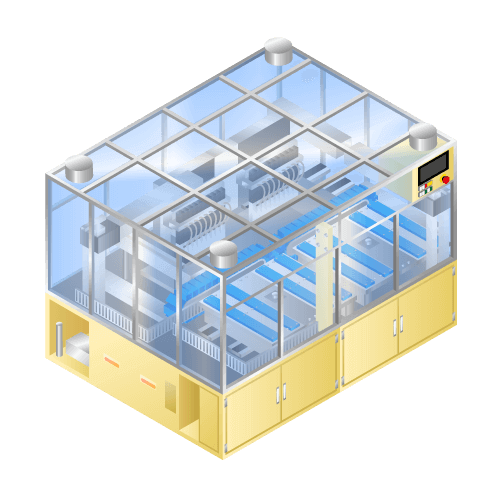

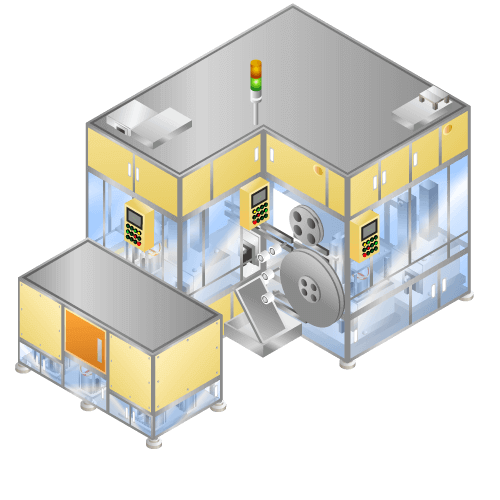

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

-

Single Wafer (sheet shaped) Film Transportation

Technology to transport film which is thin and does not have body, without making a scratch or trace. Single wafer (sheet shaped) film easily generates static electricity compared with roll film, therefore it requires adequate countermeasures against static electricity. In the case of removal from stock area, countermeasures are required to avoid taking more than pieces of 2 film at a time. This technology has proven invaluable in the transport of sheet shaped film.

See machines using this technology > -

The Machine on Single Wafer (sheet shaped) Film Transportation

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Laminate three sided heat seal machine for lithium-ion secondary batteries etc.

Machine to seal laminate film which rolled up electrodes such as lithium-ion batteries, etc. with heater block.

-

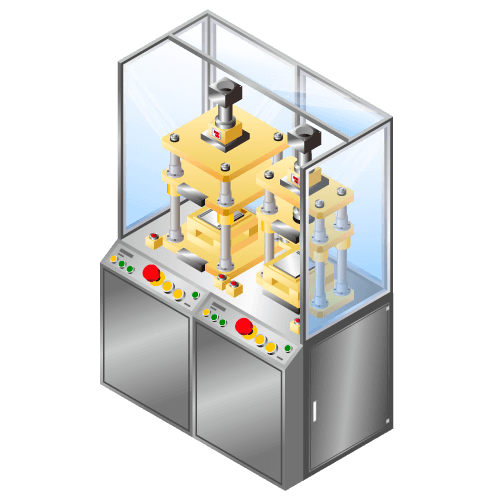

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

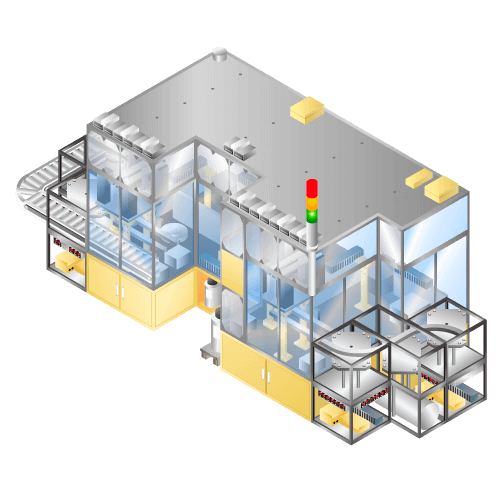

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Battery Material Handling

Some materials used for secondary batteries, such as lithium-ion etc., need special handling. The electrode should be handled at high speed without causing damage to fragile active material. In the electrolyte, special consideration is required for prevention of the generation of precipitation and corrosion gas. We have extensive experience in dealing with such battery material.

See machines using this technology > -

The Machine on Battery Material Handling

-

Roll press for lithium-ion secondary batteries etc.

Machine to increase density of electrode material by pressing positive electrode or negative electrode of lithium-ion etc. with roller continuously.

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Jerry-roll (JR) insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert jerry-roll and bottom insulator to external can of cylindrical lithium-ion batteries etc.

-

Swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to swage external can of cylindrical lithium-ion batteries etc.

-

Negative-electrode welding, CP insertion and TP insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert center pin after welding negative electrode in manufacturing process of lithium-ion batteries, etc. and to insert punched out top insulator for later process.

-

Machine to place groove for cylindrical (18650) lithium-ion secondary batteries etc.

Used in the manufacturing process of items such as lithium-ion batteries, etc.

-

Laminate three sided heat seal machine for lithium-ion secondary batteries etc.

Machine to seal laminate film which rolled up electrodes such as lithium-ion batteries, etc. with heater block.

-

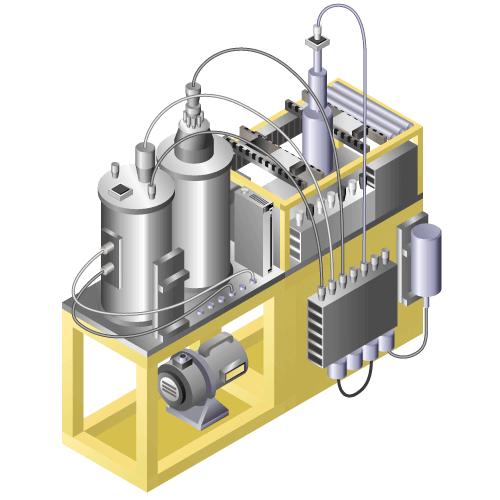

Injection machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in the manufacturing process of items such as lithium-ion batteries, etc. Developed to shorten the impregnation time by application of pressure in addition to vacuum immersion.

-

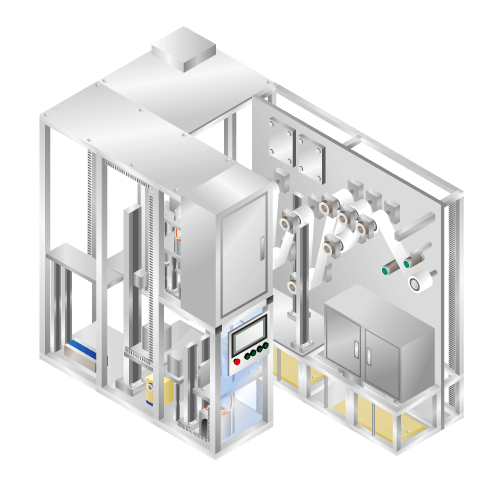

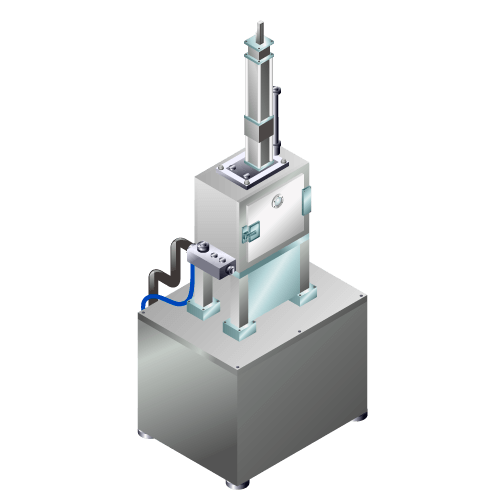

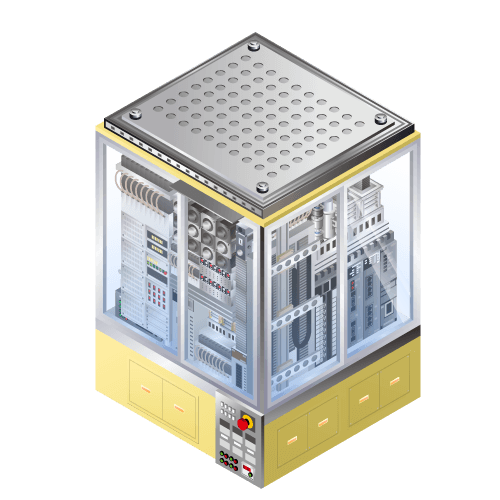

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc.

-

Sealing port swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to press and swage external can after being supplied the appropriate cell by insertion sealing port in the manufacturing process of lithium-ion batteries, etc.

-

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc. for small-quantity production

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc. This machine requires manual operation and is intended for small-quantity production.

-

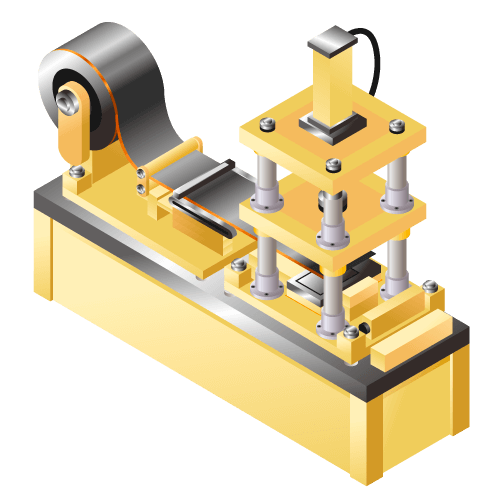

Electrode cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to cut positive or negative electrode of lithium-ion batteries etc. from original roll to batteries size. This machine requires manual operation and is intended for small-quantity production.

-

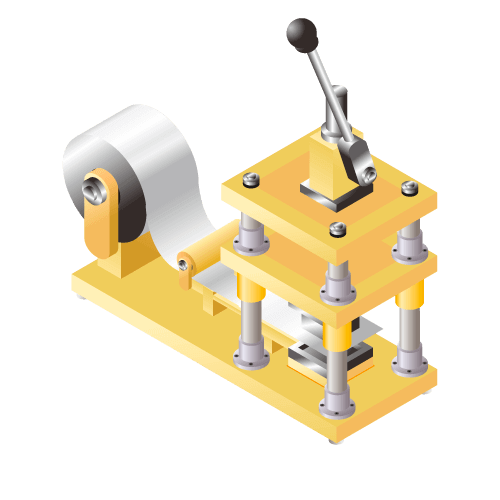

Laminate forming (cup forming) machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries etc. Machine including hand working for small-quantity production.

-

Laminate outer shape stamping machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to stamp outer shape of embossed laminate film to roll up electrodes for items such as lithium-ion batteries etc. and to make them the prescribed size. This machine requires manual operation and is intended for small-quantity production.

-

Laminate three sided heat seal machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to seal laminate film with rolled up electrodes such as lithium-ion batteries, etc. with heater block. This machine requires manual operation and is intended for small-quantity production.

-

Electrolytic injection machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries etc. This machine requires manual operation and is intended for small-quantity production.

-

Degassing and sealing machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to discharge gas produced at the first charging in manufacturing process of lithium-ion batteries etc. from batteries cell and to reseal.

-

Laminate blank space cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Jig to cut and remove margin section for accumulated gas of laminate cell of lithium-ion battery etc. Jig for manual operation and is intended for small-quantity production.

-

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

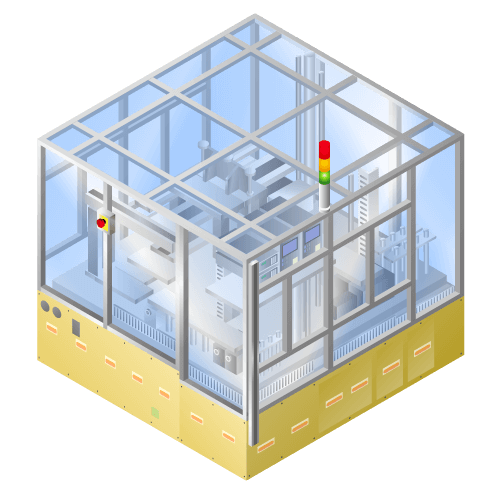

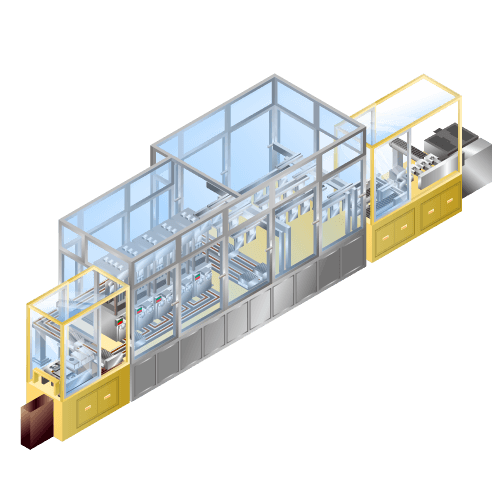

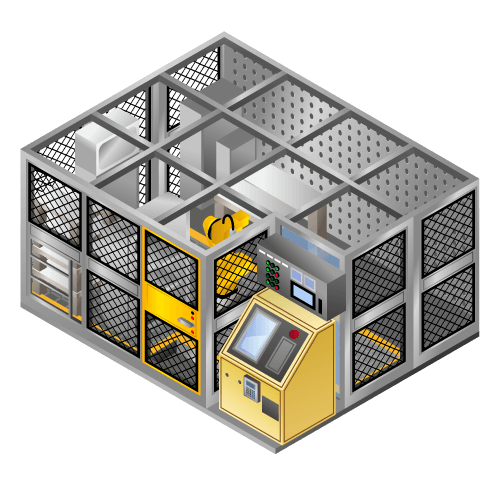

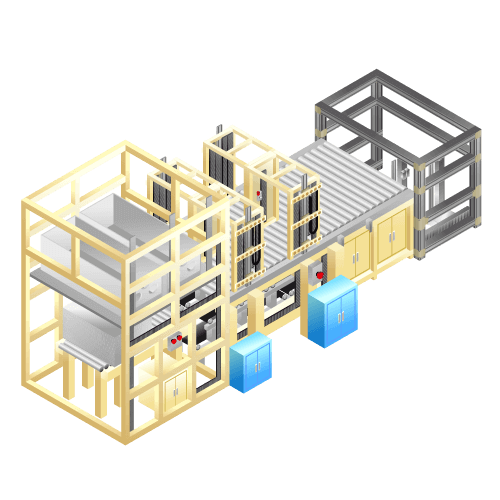

18650 cylindrical lithium-ion batteries etc. assembly line

18650 cylindrical lithium-ion batteries assembly line, consistent line from insertion of jerry roll to crimp.

-

-

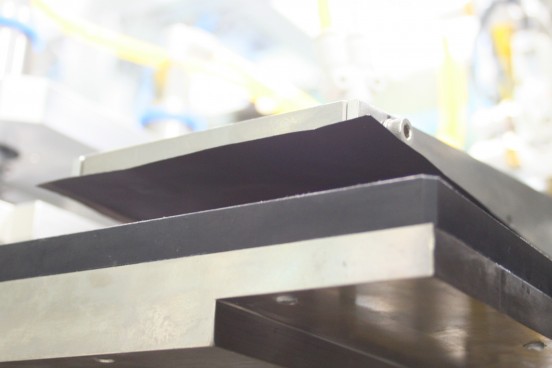

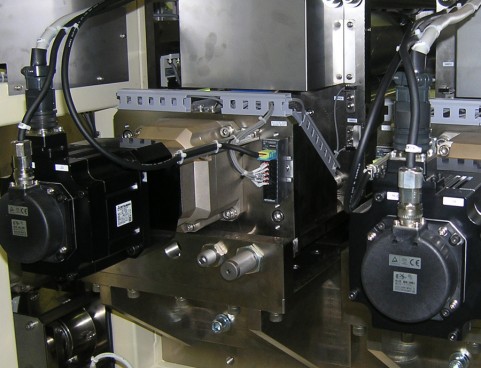

Mounting and base

Building a strong mounting and base for machinery is important for maintaining stability for the long term. A strong mounting and base also shortens the start-up time by minimizing accuracy deviation to transfer and transport mechanisms. Generally, we have eliminated the use of aluminum frames. We construct stable bases using thick square logs and a substantial base for the can manufacturing process. For various requirements, we do annealing and use a mount with additional accuracy.

See machines using this technology > -

The Machine on Mounting and base

-

Roll press for lithium-ion secondary batteries etc.

Machine to increase density of electrode material by pressing positive electrode or negative electrode of lithium-ion etc. with roller continuously.

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

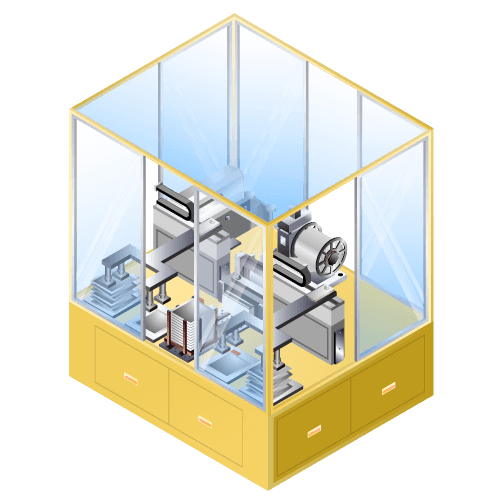

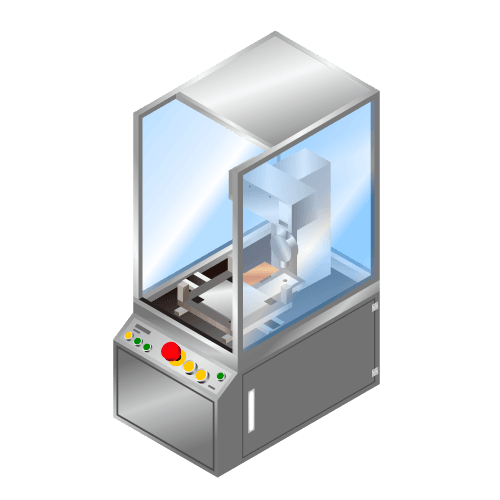

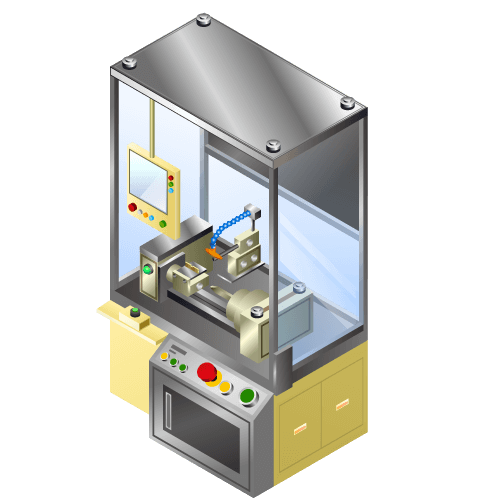

Probe Pin Processing Machine

Machine to give sharply-angled taper processing to cylindrical metallic material with diameter of 0.1mm or less.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Jerry-roll (JR) insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert jerry-roll and bottom insulator to external can of cylindrical lithium-ion batteries etc.

-

Swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to swage external can of cylindrical lithium-ion batteries etc.

-

Negative-electrode welding, CP insertion and TP insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert center pin after welding negative electrode in manufacturing process of lithium-ion batteries, etc. and to insert punched out top insulator for later process.

-

Machine to place groove for cylindrical (18650) lithium-ion secondary batteries etc.

Used in the manufacturing process of items such as lithium-ion batteries, etc.

-

Laminate three sided heat seal machine for lithium-ion secondary batteries etc.

Machine to seal laminate film which rolled up electrodes such as lithium-ion batteries, etc. with heater block.

-

Injection machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in the manufacturing process of items such as lithium-ion batteries, etc. Developed to shorten the impregnation time by application of pressure in addition to vacuum immersion.

-

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc.

-

Sealing port swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to press and swage external can after being supplied the appropriate cell by insertion sealing port in the manufacturing process of lithium-ion batteries, etc.

-

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Automobile security parts assembly

Machine to assemble more than 10 different parts in resin parts with diameter of approx. 50mm. The parts used for each product type are different, therefore machine has the function of selecting parts used automatically with change of type.

-

Automobile plumbing components

Assembly machine for automobile parts. Machine to assemble resin parts including laser welding, check air tightness and flow volume.

-

Seal material coating applicator (with course correcting function)

Machine to have correct seal material application imperviously to work variability by correction of application trajectory with measuring work shape. High performance application machine including material heating function, pneumatic transportation of high viscosity material, UV curing process, inspection process after application and data collection function.

-

Piston ring groove processing machine

Machine to groove for "piston ring" for fixing to piston used in internal combustion.

-

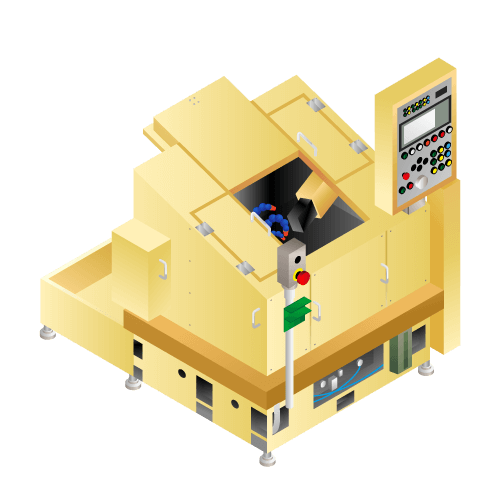

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

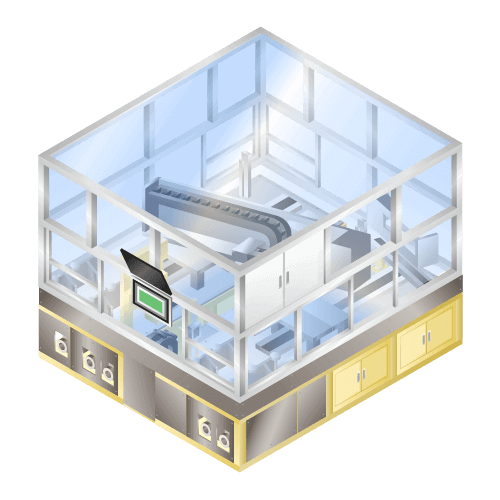

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

18650 cylindrical lithium-ion batteries etc. assembly line

18650 cylindrical lithium-ion batteries assembly line, consistent line from insertion of jerry roll to crimp.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

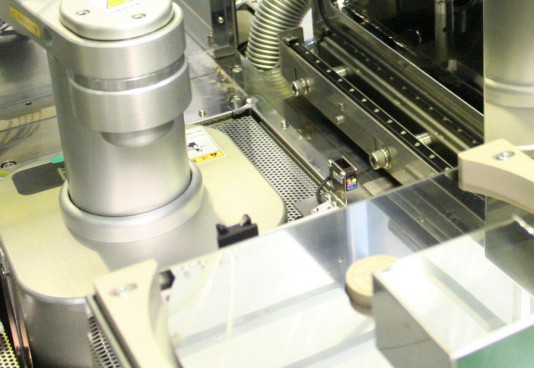

Adhesive Technology of Single Wafer (sheet shaped) Film to Roll Film

We have the technology to adhere single wafer (sheet shaped) film to roll film without scratches or air bubbles. This mainly applies to the adhering of optical film for items such as flat displays and touch panels and the like. Adhering, roll laminate is generally desirable and responds to both cold and heat. Our machines can adhere film from a width of 50 to 60mm to more than 1m. It is also possible to automate the peeling of the peel separator and protection film not only in roll film applications but also with single wafer (sheet shaped) film..

See machines using this technology > -

The Machine on Adhesive Technology of Single Wafer (sheet shaped) Film to Roll Film

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

-

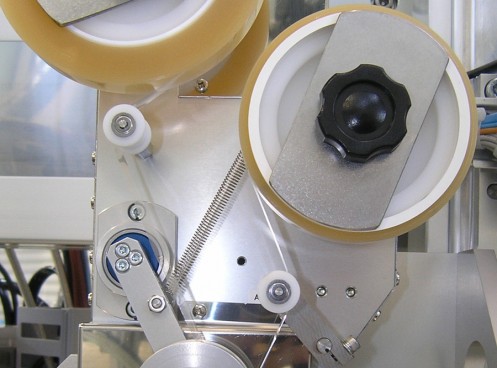

Film Stripping Technology

In the case of adhering single wafer (sheet shaped) film, peeling of the separator or protection film may be needed before adhering. We have developed a new film stripping technology which allows for the peeling of the separator and protection film adhered to the edge of the film of the same size without damaging the film. We have achieved a continuously stable operating rate by allowing for multiple peeling profiles to deal with variation in the peeling strength of a lot.

See machines using this technology > -

The Machine on Film Stripping Technology

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Two up prevention of film

It is a technology that prevents the two up when loading one by one the film straight-loading state. The cause of the two up and mainly include “glue each other to adhere the end,” ” between the two eyes at the time of adsorption rise becomes a vacuum state,” ” static electricity is generated by peeling electrification.” Two up by weaving a mechanism to prevent these in the loading section and reduce to an absolute minimum. It also prevented from flowing to the post-process in the two take-up of any chance by also equipped with two up detection sensor.

See machines using this technology > -

The Machine on Two up prevention of film

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Precise positioning

We have technology and experience to realize alignment system with high cost performance according to needs such as mechanism positioning and image processing. To maintain accuracy for the long term, we realize not only camera or positioning table but also precise positioning including design of mounting.

See machines using this technology > -

The Machine on Precise positioning

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Jerry-roll (JR) insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert jerry-roll and bottom insulator to external can of cylindrical lithium-ion batteries etc.

-

Swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to swage external can of cylindrical lithium-ion batteries etc.

-

Negative-electrode welding, CP insertion and TP insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert center pin after welding negative electrode in manufacturing process of lithium-ion batteries, etc. and to insert punched out top insulator for later process.

-

Machine to place groove for cylindrical (18650) lithium-ion secondary batteries etc.

Used in the manufacturing process of items such as lithium-ion batteries, etc.

-

Laminate three sided heat seal machine for lithium-ion secondary batteries etc.

Machine to seal laminate film which rolled up electrodes such as lithium-ion batteries, etc. with heater block.

-

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc.

-

Sealing port swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to press and swage external can after being supplied the appropriate cell by insertion sealing port in the manufacturing process of lithium-ion batteries, etc.

-

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Automobile security parts assembly

Machine to assemble more than 10 different parts in resin parts with diameter of approx. 50mm. The parts used for each product type are different, therefore machine has the function of selecting parts used automatically with change of type.

-

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

18650 cylindrical lithium-ion batteries etc. assembly line

18650 cylindrical lithium-ion batteries assembly line, consistent line from insertion of jerry roll to crimp.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Film cut

We have experience of various cutting method such as round blade, shear blade, Thomson blade、chisel and ultrasonic wave etc. In consideration of material of object, size, tact and cost, we suggest the most suitable spec.

See machines using this technology > -

The Machine on Film cut

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

-

Servo-control

We have enough experience of multiaxis servo control through processing machine and related device for film. Respond to various controls such as multiple synchronizing control and multiple interpolating control etc. NC control is also available.

See machines using this technology > -

The Machine on Servo-control

-

Probe Pin Processing Machine

Machine to give sharply-angled taper processing to cylindrical metallic material with diameter of 0.1mm or less.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Piston ring groove processing machine

Machine to groove for "piston ring" for fixing to piston used in internal combustion.

-

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

-

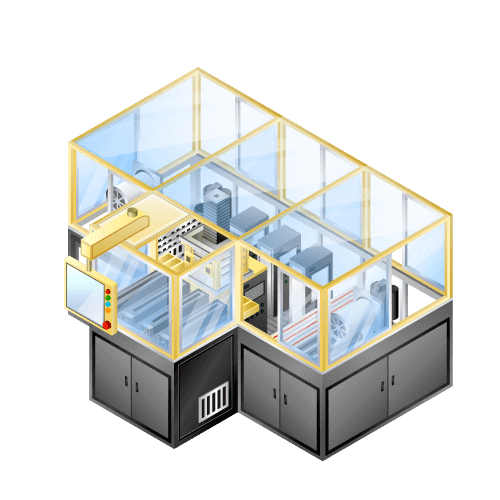

Clean Technology

It is not just a matter of constructing machinery using clean production protocols. We take comprehensive measures to ensure the work is free of contamination and contaminant containment. In addition to design and manufacturing we pay careful attention to packing, transportation and installation as well. We have developed this system to allow us to maintain a necessary of cleanliness and reduce costs at the same time. This technology has been used for the production of liquid crystals, semiconductors and precision instruments with classes ranging from 10 to 10,000.

See machines using this technology > -

The Machine on Clean Technology

-

Compact Sensor Assembly Machine

Machine to assemble compact sensors with a size of a few millimeters

-

Chemical Injection Machine

Machine to inject chemicals into a special container without air bubbles quickly and accurately.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Countermeasures against Static Electricity (ESD)

Work has a damaging effect by static electricity and disturb stability of film transportation by static electricity. Therefore we need to have technology to stop static generation and remove generated static electricity. Almost all static electricity generated in machine is caused by peel electrification or frictional electrification. We design to make every effort to avoid these electrifications and construct effective neutralization method against generated static electricity by multiple measures of structure and neutralization apparatus.

See machines using this technology > -

The Machine on Countermeasures against Static Electricity (ESD)

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

18650 cylindrical lithium-ion batteries etc. assembly line

18650 cylindrical lithium-ion batteries assembly line, consistent line from insertion of jerry roll to crimp.

-

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

Overseas Installations

We have performed installations and initial training in the U.S., Brazil, UK, Germany, India, Philippines, China, S. Korea, etc. For overseas installation start ups, both options of teaching local workers as supervisors or sending supervisory workers are available. Any information such as operation manuals can be provided in any language.

See machines using this technology > -

The Machine on Overseas Installations

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Jerry-roll (JR) insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert jerry-roll and bottom insulator to external can of cylindrical lithium-ion batteries etc.

-

Automobile plumbing components

Assembly machine for automobile parts. Machine to assemble resin parts including laser welding, check air tightness and flow volume.

-

-

Measure for safety

The safety is of utmost importance. However, we must avoid great increasing in cost or reduction of workability otherwise merit of automatization is down by half. We have technology and experience to realize high safety without losing cost and workability as much as possible. Then we also respond to safety PLC.

See machines using this technology > -

The Machine on Measure for safety

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

Probe Pin Processing Machine

Machine to give sharply-angled taper processing to cylindrical metallic material with diameter of 0.1mm or less.

-

Compact Sensor Assembly Machine

Machine to assemble compact sensors with a size of a few millimeters

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to swage external can of cylindrical lithium-ion batteries etc.

-

Negative-electrode welding, CP insertion and TP insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert center pin after welding negative electrode in manufacturing process of lithium-ion batteries, etc. and to insert punched out top insulator for later process.

-

Machine to place groove for cylindrical (18650) lithium-ion secondary batteries etc.

Used in the manufacturing process of items such as lithium-ion batteries, etc.

-

Injection machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in the manufacturing process of items such as lithium-ion batteries, etc. Developed to shorten the impregnation time by application of pressure in addition to vacuum immersion.

-

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc.

-

Sealing port swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to press and swage external can after being supplied the appropriate cell by insertion sealing port in the manufacturing process of lithium-ion batteries, etc.

-

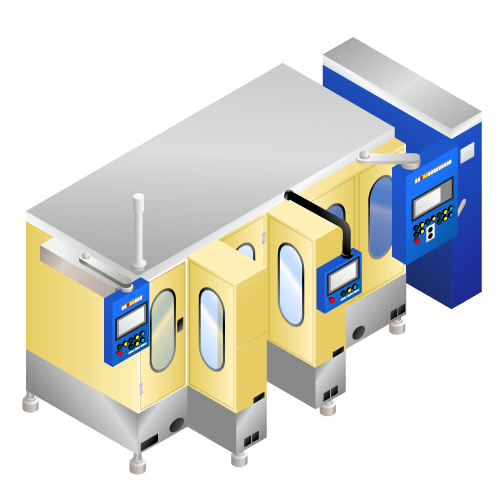

Twin fluid washing machine (catalog sales)

Washing machine which has the characteristics of machine cost and running cost reduction.

-

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

Electrode cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to cut positive or negative electrode of lithium-ion batteries etc. from original roll to batteries size. This machine requires manual operation and is intended for small-quantity production.

-

Laminate forming (cup forming) machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries etc. Machine including hand working for small-quantity production.

-

Laminate outer shape stamping machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to stamp outer shape of embossed laminate film to roll up electrodes for items such as lithium-ion batteries etc. and to make them the prescribed size. This machine requires manual operation and is intended for small-quantity production.

-

Laminate blank space cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Jig to cut and remove margin section for accumulated gas of laminate cell of lithium-ion battery etc. Jig for manual operation and is intended for small-quantity production.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Automobile security parts assembly

Machine to assemble more than 10 different parts in resin parts with diameter of approx. 50mm. The parts used for each product type are different, therefore machine has the function of selecting parts used automatically with change of type.

-

Automobile plumbing components

Assembly machine for automobile parts. Machine to assemble resin parts including laser welding, check air tightness and flow volume.

-

Brush washing machine

Machine to take out engine parts aligned on pallet one by one automatically and remove contamination generated in processing by special brush pouring wash solution in washing bath. After washing, blow solution and discharge parts to designated place of pallet.

-

Seal material coating applicator (with course correcting function)

Machine to have correct seal material application imperviously to work variability by correction of application trajectory with measuring work shape. High performance application machine including material heating function, pneumatic transportation of high viscosity material, UV curing process, inspection process after application and data collection function.

-

Piston ring groove processing machine

Machine to groove for "piston ring" for fixing to piston used in internal combustion.

-

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-

-

Adhesive technology of roll film

We have the technology to adhere roll film without making scratches or air bubbles. This mainly applies to the adhering of optical film for items such as flat displays and touch panels and the like. In adhering, roll laminate is generally desirable and responds to both cold and heat. Our machines can adhere film 50 or 60mm to 1m or more. Not only continuous laminate but also intermittent laminate with low tension are both supported.

See machines using this technology > -

The Machine on Adhesive technology of roll film

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-