Complied matters

We received order of this machine from trade. The trade received the similar machine from some customer, but capacity of the trade's machine has too small. Therefore, the trade tried to find subcontract. The machine spec received by this trade is for very big size items with length of 20m and height of 5m or more. Therefore, it was very difficult for the trade to find subcontract and time has passed. When we received a request about this project from the trade, we only had brief period to deliver. Meanwhile, we put together an organization to deliver it in requested delivery time and could deliver it incomprehensible under normal case.

Technology used

-

Glass Transportation Technology

We have the technology and experience to transport G8 glass with size of 2 x 2m and thickness of 1mm or less. It is able to safely and stably handle large delicate work which is easy to break under it’s own weight.

See machines using this technology > -

The Machine on Glass Transportation Technology

-

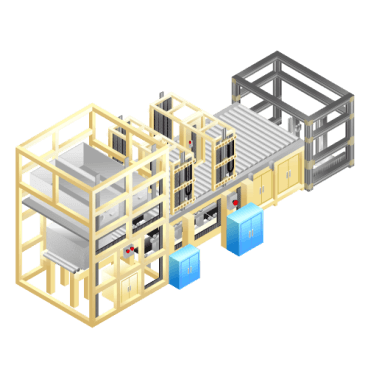

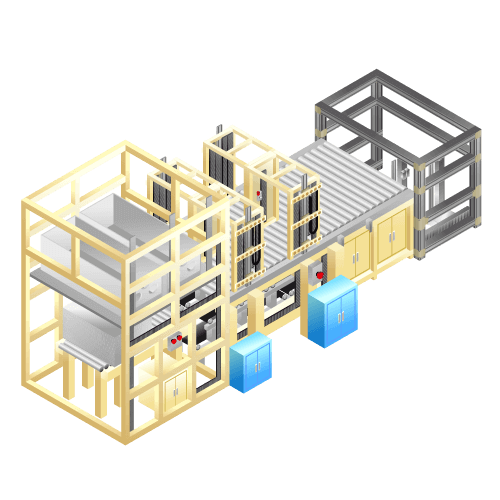

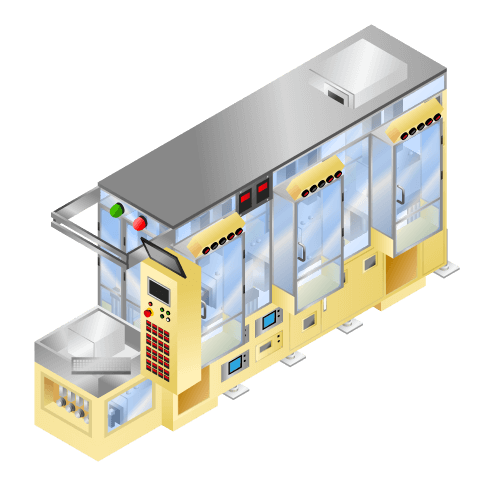

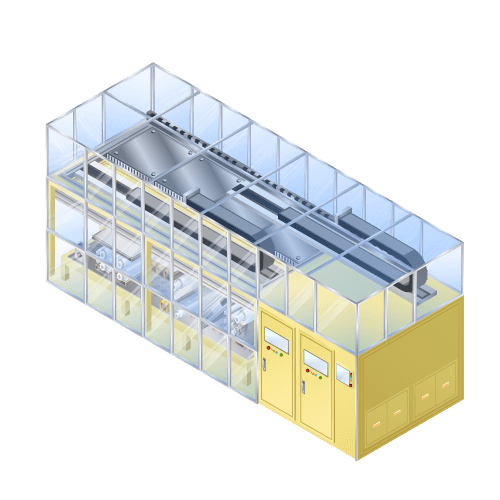

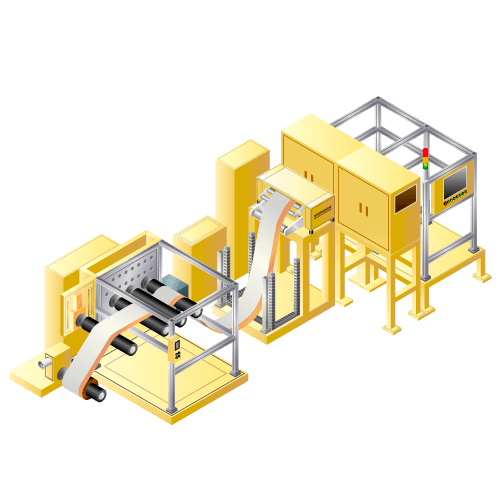

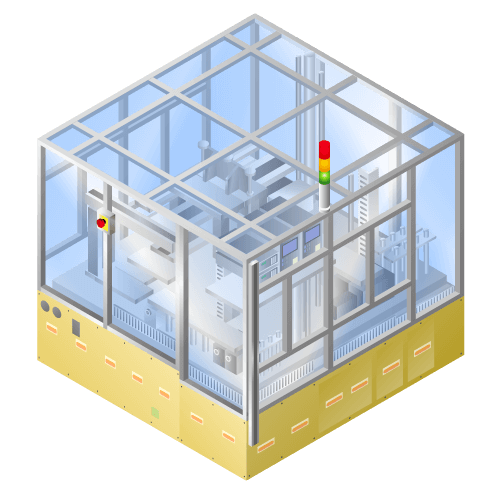

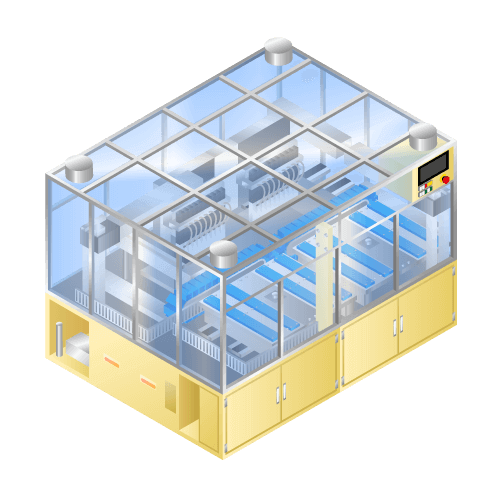

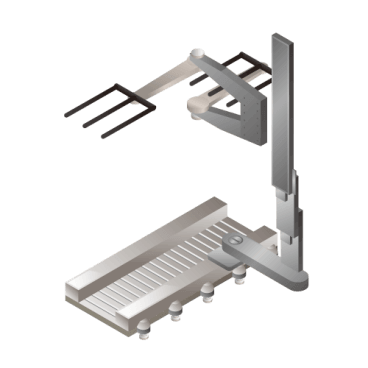

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

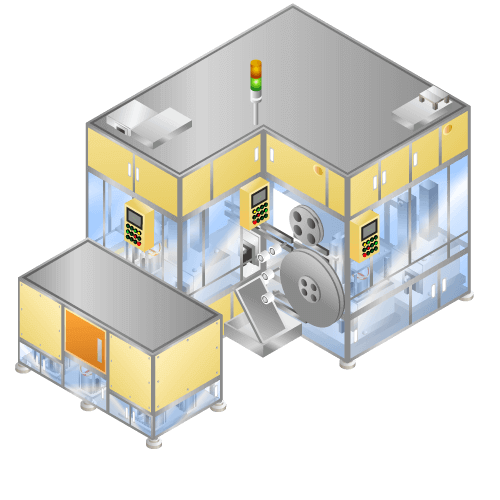

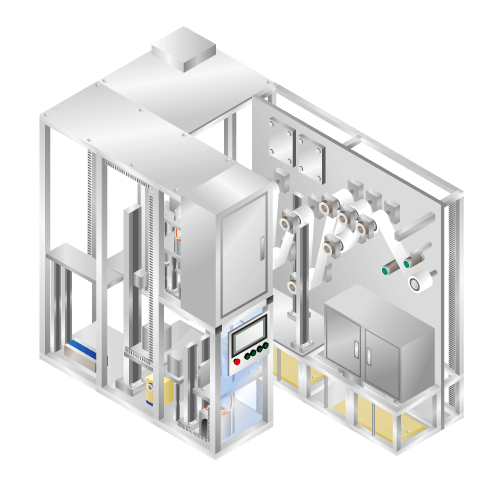

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-

-

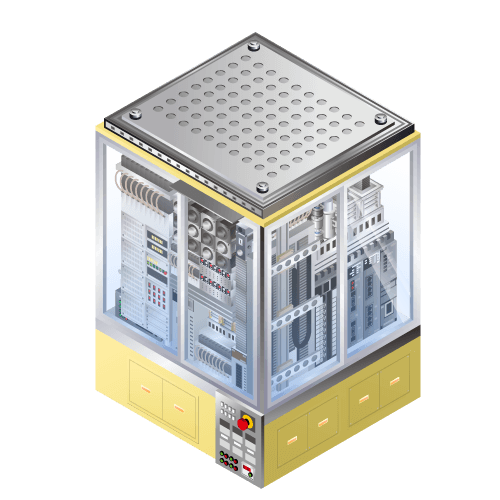

Sequencer control

Respond to almost all PLC such as Mitsubishi, Omron, Keyence and Siemens etc. Also available for traceability, MES and safety PLC.

See machines using this technology > -

The Machine on Sequencer control

-

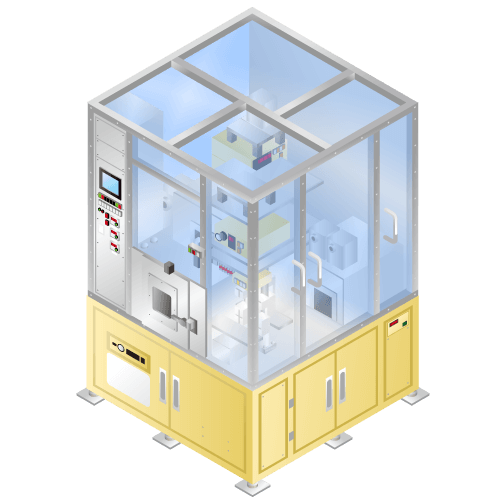

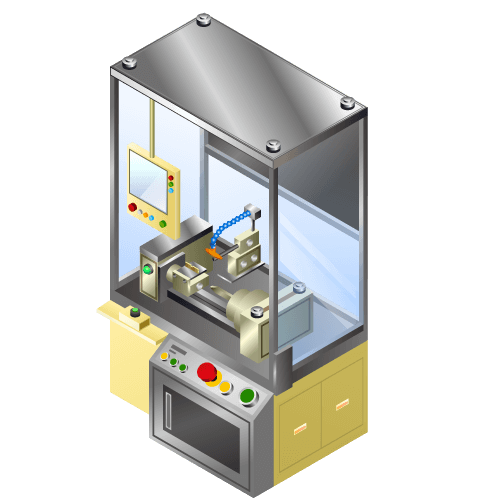

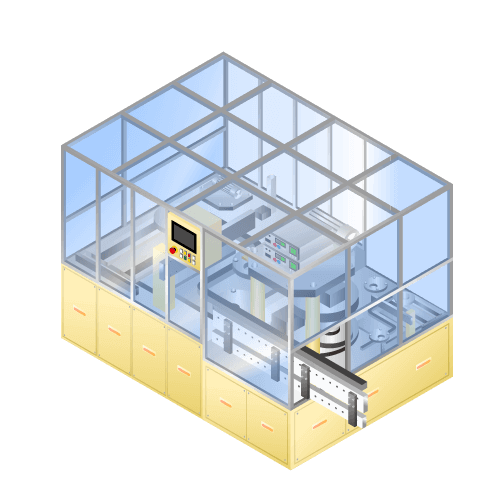

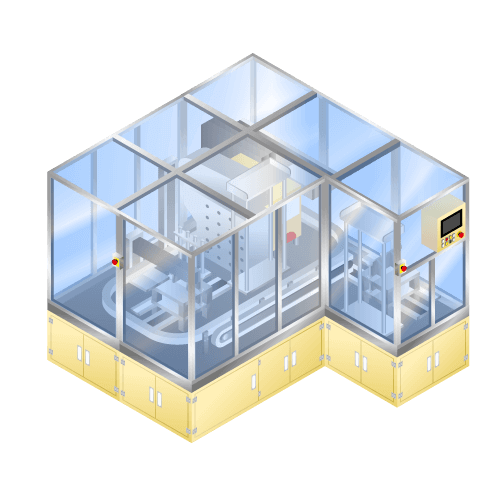

Compact Sensor Assembly Machine

Machine to assemble compact sensors with a size of a few millimeters

-

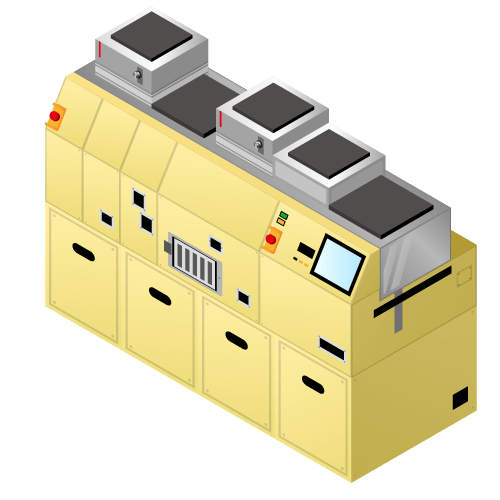

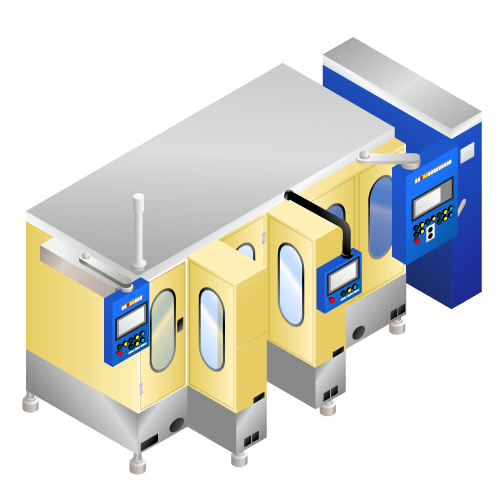

Twin fluid washing machine (catalog sales)

Washing machine which has the characteristics of machine cost and running cost reduction.

-

Automobile security parts assembly

Machine to assemble more than 10 different parts in resin parts with diameter of approx. 50mm. The parts used for each product type are different, therefore machine has the function of selecting parts used automatically with change of type.

-

Automobile plumbing components

Assembly machine for automobile parts. Machine to assemble resin parts including laser welding, check air tightness and flow volume.

-

Brush washing machine

Machine to take out engine parts aligned on pallet one by one automatically and remove contamination generated in processing by special brush pouring wash solution in washing bath. After washing, blow solution and discharge parts to designated place of pallet.

-

Seal material coating applicator (with course correcting function)

Machine to have correct seal material application imperviously to work variability by correction of application trajectory with measuring work shape. High performance application machine including material heating function, pneumatic transportation of high viscosity material, UV curing process, inspection process after application and data collection function.

-

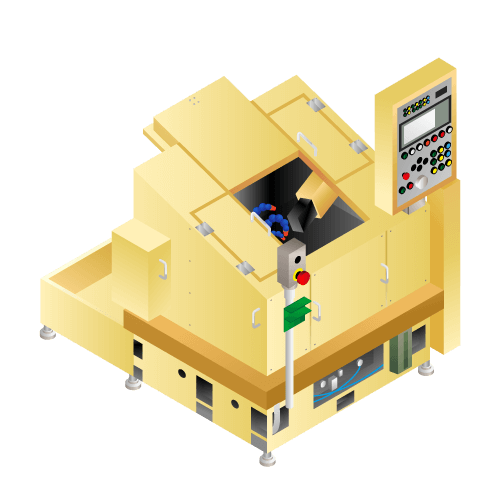

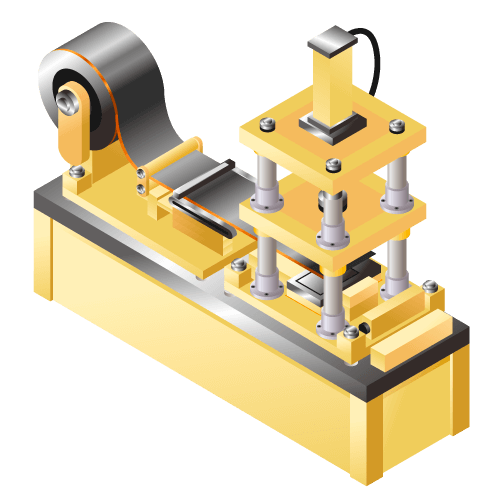

Piston ring groove processing machine

Machine to groove for "piston ring" for fixing to piston used in internal combustion.

-

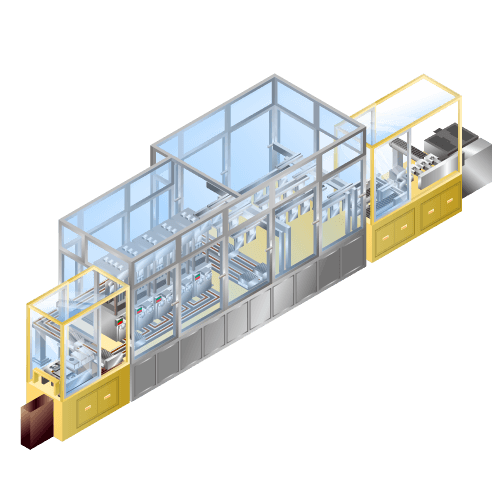

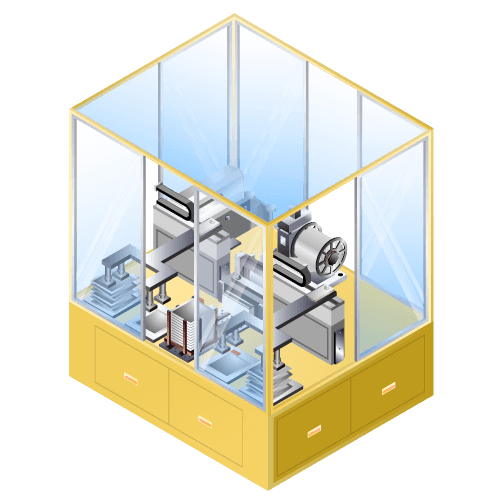

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

-

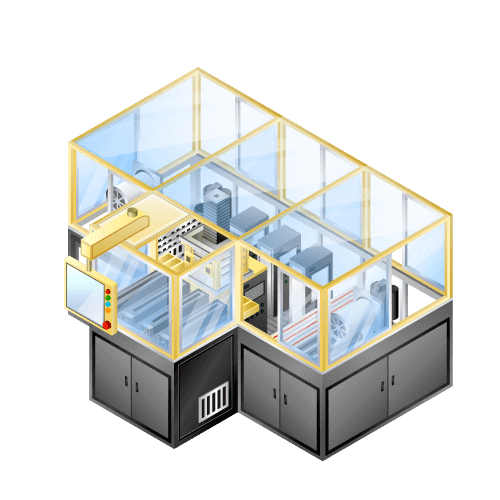

Factory space

We have an area of approx. 3000㎡ in head office and factory. And if includes network of partners, we can free up assemble area with more than 10,000㎡. So We respond to assembly of large machinery and large quantity of machines.

See machines using this technology > -

The Machine on Factory space

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

-

Countermeasures against Static Electricity (ESD)

Work has a damaging effect by static electricity and disturb stability of film transportation by static electricity. Therefore we need to have technology to stop static generation and remove generated static electricity. Almost all static electricity generated in machine is caused by peel electrification or frictional electrification. We design to make every effort to avoid these electrifications and construct effective neutralization method against generated static electricity by multiple measures of structure and neutralization apparatus.

See machines using this technology > -

The Machine on Countermeasures against Static Electricity (ESD)

-

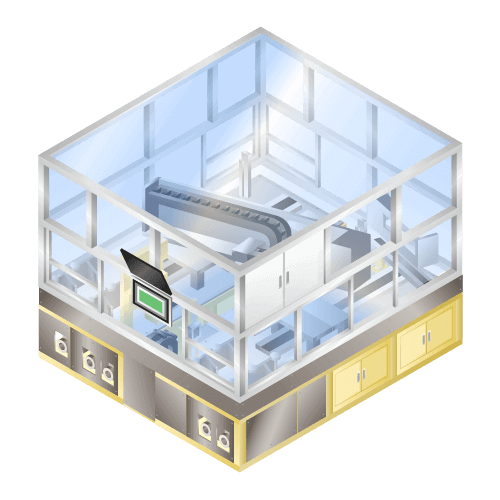

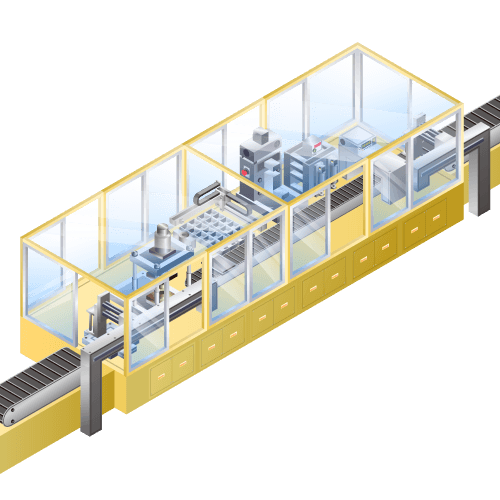

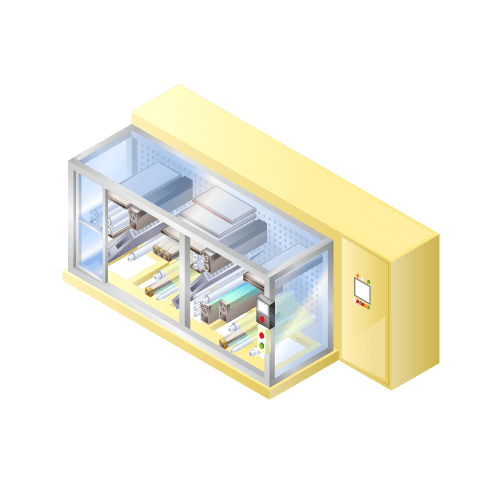

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

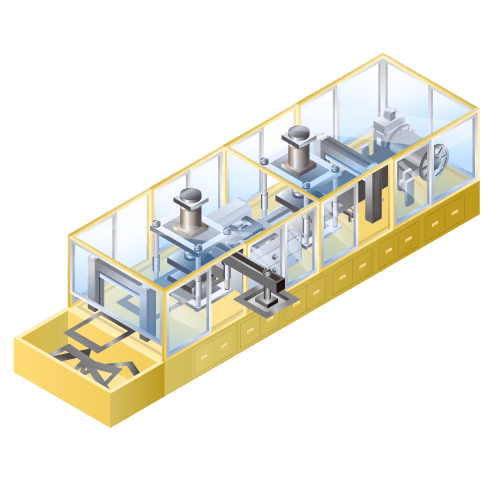

Laminating machine (zigzag system) for layered lithium-ion batteries etc.

Machine to layer electrode of layered lithium-ion batteries etc.. System to insert positive and negative electrode to separator folded in a zig-zag manner alternately.

-

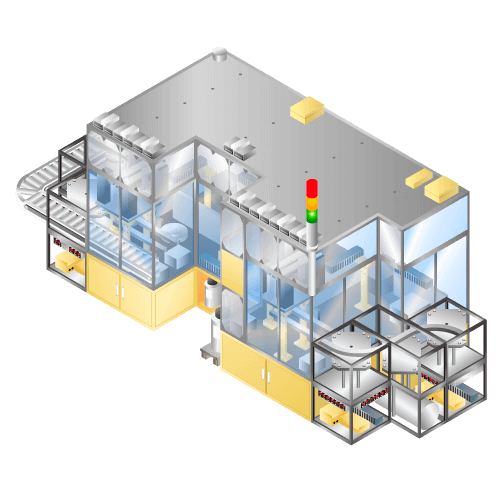

18650 cylindrical lithium-ion batteries etc. assembly line

18650 cylindrical lithium-ion batteries assembly line, consistent line from insertion of jerry roll to crimp.

-

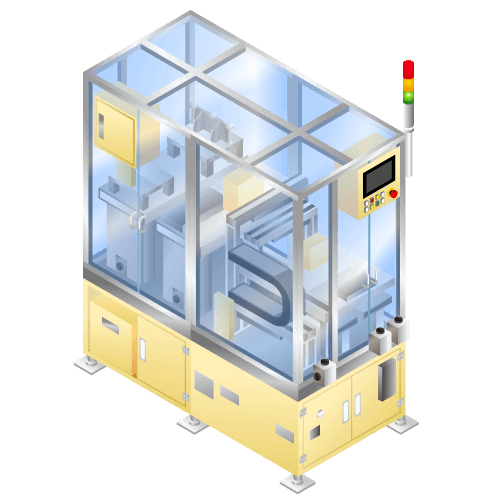

Single wafer processing film adhering machine

Machine to apply two types of single wafer (sheet shaped) films automatically with a high degree of accuracy without scratches or air bubbles. Each film has a protection film and separator (mold releasing film), which are removed automatically while feeding.

-

-

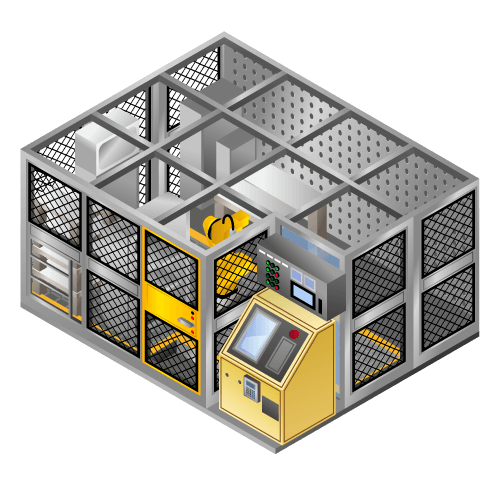

Measure for safety

The safety is of utmost importance. However, we must avoid great increasing in cost or reduction of workability otherwise merit of automatization is down by half. We have technology and experience to realize high safety without losing cost and workability as much as possible. Then we also respond to safety PLC.

See machines using this technology > -

The Machine on Measure for safety

-

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

-

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

-

TAB ultrasonic welder for lithium-ion secondary batteries etc.

Machine to weld collecting tab to electrodes of lithium-ion batteries, etc.

-

Laminate forming machine for lithium-ion secondary batteries etc.

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries, etc.

-

Probe Pin Processing Machine

Machine to give sharply-angled taper processing to cylindrical metallic material with diameter of 0.1mm or less.

-

Compact Sensor Assembly Machine

Machine to assemble compact sensors with a size of a few millimeters

-

Sheet to Roll Optical Film Adhering Machine

Machine to adhere 1 sq. meter sheet-shaped film or more with a clearance of 0.5mm to roll film with a width of 1meter or more continuously. Adhered roll films are cut to make sheet-shaped films and are stored.

-

Swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to swage external can of cylindrical lithium-ion batteries etc.

-

Negative-electrode welding, CP insertion and TP insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert center pin after welding negative electrode in manufacturing process of lithium-ion batteries, etc. and to insert punched out top insulator for later process.

-

Machine to place groove for cylindrical (18650) lithium-ion secondary batteries etc.

Used in the manufacturing process of items such as lithium-ion batteries, etc.

-

Injection machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in the manufacturing process of items such as lithium-ion batteries, etc. Developed to shorten the impregnation time by application of pressure in addition to vacuum immersion.

-

Electrolytic injection machine for lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries, etc.

-

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc.

-

Sealing port swaging machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to press and swage external can after being supplied the appropriate cell by insertion sealing port in the manufacturing process of lithium-ion batteries, etc.

-

Twin fluid washing machine (catalog sales)

Washing machine which has the characteristics of machine cost and running cost reduction.

-

Laminating machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy. Unlike the case of production machines, this machine has the priority of machine cost over processing speed.

-

Electrode cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to cut positive or negative electrode of lithium-ion batteries etc. from original roll to batteries size. This machine requires manual operation and is intended for small-quantity production.

-

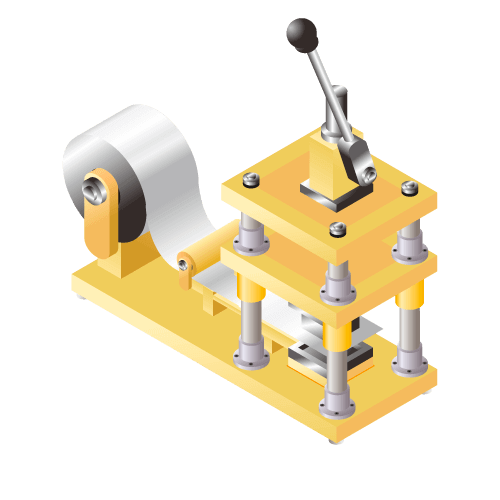

Laminate forming (cup forming) machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to get depression for placing electrodes by embossing laminate film to make packing for rolling up electrodes such as lithium-ion batteries etc. Machine including hand working for small-quantity production.

-

Laminate outer shape stamping machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to stamp outer shape of embossed laminate film to roll up electrodes for items such as lithium-ion batteries etc. and to make them the prescribed size. This machine requires manual operation and is intended for small-quantity production.

-

Laminate blank space cutting machine for lithium-ion secondary batteries etc. for small-quantity production

Jig to cut and remove margin section for accumulated gas of laminate cell of lithium-ion battery etc. Jig for manual operation and is intended for small-quantity production.

-

Laminating machine with alignment function for film

Machine to apply heat laminate to each supplied film roll with heated roller. Normally, in case of laminating each film roll, apply only width direction by EPC etc, preventing position gap. However, it is able to adjust the position of not only the width direction but also the flow direction by controlling the amount of both feeds.

-

Automobile security parts assembly

Machine to assemble more than 10 different parts in resin parts with diameter of approx. 50mm. The parts used for each product type are different, therefore machine has the function of selecting parts used automatically with change of type.

-

Automobile plumbing components

Assembly machine for automobile parts. Machine to assemble resin parts including laser welding, check air tightness and flow volume.

-

Brush washing machine

Machine to take out engine parts aligned on pallet one by one automatically and remove contamination generated in processing by special brush pouring wash solution in washing bath. After washing, blow solution and discharge parts to designated place of pallet.

-

Seal material coating applicator (with course correcting function)

Machine to have correct seal material application imperviously to work variability by correction of application trajectory with measuring work shape. High performance application machine including material heating function, pneumatic transportation of high viscosity material, UV curing process, inspection process after application and data collection function.

-

Piston ring groove processing machine

Machine to groove for "piston ring" for fixing to piston used in internal combustion.

-

Transfer machine (processing machine for several processes)

Machine to process 5 processes such as boring, grooving and C side processing etc. with transporting work on a separate station in order. Some processes employ CNC control to get high accuracy processing.

-

Large size glass carrier machine

Loading machine to take out thin glass with size of 2000mm square or more from storage and transport.

-

Liquid crystal injection machine

Machine to inject liquid crystal into LCD one by one under vacuum after drying LCD input by magazine in a vacuum.

-